Are you interested in learning more about anyLogistix? Leading companies around the globe use it for their supply chain purposes, including inventory decision-making. Check our case studies to see the benefits in action.

Did you know that businesses can lose up to 20% of potential revenue due to poor inventory management and decision-making? In fact, inventory planning significantly impacts supply chain costs, and studies show that effective management can lead to substantial cost savings.

In our previous blog on inventory planning, we have already covered process flows, along with the objectives. However, in this article, we will dive deeper into how you can use anyLogistix to successfully optimize inventory decision-making. Follow along as we explore the powerful capabilities of the software in detail.

Contents:

Inventory planning ensures your business has exactly what is needed—no more, no less. It’s the process of managing the quantities and timing of stock to align perfectly with customer demand. It is an important practice, as this translates into a company's ability to satisfy customers without wasting resources.

Inventory decision-making balances the scale of too much and too little through predicting sales, setting reorder points, and maintaining safety stock levels. This prevents the possible scenario of either being overloaded with unsold items or turning customers away because the shelves are empty.

Efficient planning of your inventory gets your operations organized, reduces costs, and enhances customer satisfaction by having in store whatever they may need at any given time.

To begin our journey towards successful inventory decision-making, let’s define inventory policies. So, what are they?

Inventory policies are the guidelines businesses follow to manage their stock efficiently. These rules help in achieving a proper balance between having enough products to meet customer demand while avoiding overstocking.

There are a number of inventory policies, but the following are some of the most common:

Each of these strategies is selected based on the needs of a company and its operational goals regarding efficiency and cost-effectiveness within its inventory planning.

Selecting the right inventory policy involves understanding your business needs—like demand patterns, lead times, and variability in supply.

anyLogistix provides tools for the simulation of different inventory strategies, showing how each strategy will perform under various scenarios. This capability helps ensure that you select the most effective policy to optimize both efficiency and cost-effectiveness in your supply chain management.

However, there are times when customization is necessary. In that case, we've got you covered—anyLogistix allows you to define any custom inventory policies to meet the specific needs of your business. Note that inventory policies in anyLogistix are available only within simulation-based experiments.

Are you interested in learning more about anyLogistix? Leading companies around the globe use it for their supply chain purposes, including inventory decision-making. Check our case studies to see the benefits in action.

Material Requirements Planning (MRP) is a system for efficient control of inventory and the process of production planning. MRP calculates the materials needed and schedules their delivery based on production forecasts to make sure that everything required for manufacturing is available at the right time.

anyLogistix supports MRP by simulating its impact on your inventory system and optimizing the ordering schedules to improve overall inventory planning. This helps in reducing the level of stock while avoiding production losses due to material shortages.

Consider, for example, a company manufacturing bicycles. MRP would determine the exact amount of steel, tires, and seats needed each month, based on the production schedule, to meet customer orders without overstocking.

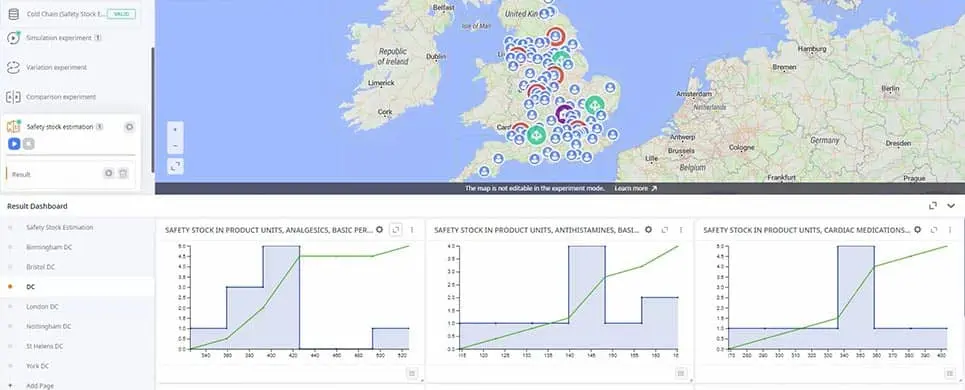

Safety stock is extra inventory on hand to safeguard against sudden rises in demand or delays in supply. This enables a business to continue selling to customers without interruption. anyLogistix helps optimize this buffer by simulating various market scenarios and calculating the ideal safety stock levels. This prevents stockouts and minimizes excess inventory costs in your decision-making process.

A winter coat seller can use anyLogistix to calculate the level of safety stock based on the historical data of sales and forecasted weather, and possibly even the reliability of the suppliers. This ensures they have enough coats during a sudden cold snap without overinvesting in inventory that might not sell.

To learn more about safety stock estimation, watch our how-to video below.

Service levels significantly impact customer satisfaction and retention, indicating how well a business meets customer demands for product availability and delivery times. High service levels mean customers get what they want at the right time, which builds their loyalty and trust in a brand.

anyLogistix helps achieve this by using advanced simulation tools that analyze and forecast demand patterns. Businesses can optimize their inventory levels accordingly with the right balance that meets customer demand and at the same time minimizes excess stock.

Effective inventory management is a fine balance between meeting your customers’ demands and managing your resources wisely.

Whether you're adjusting your current practices or implementing new strategies, anyLogistix offers the functionality and flexibility needed to refine your approach. Test it yourself and see how it transforms your inventory decision-making!